ALBÉA: A Leading Position!

2023/03/06

LUXE PACK New York 20th Anniversary Pioneers

We are thrilled to be showcasing a very exclusive group of exhibitors who have been part of the 20-year LUXE PACK New York lineage. We are honored to have them continue be part of the invaluable industry legacy that solidifies them as long-running industry packaging players. We would like to introduce them to you individually and therefore welcome you to hone on the special editorial content developed to showcase their own industry legacy and how they plan to continue to contribute to the industry’s next 20.

Articles written by Jean-Yves Bourgeois, Co-founder, LUXE PACK & Founder of Formes de Luxe Magazine

The Albéa Group has had a strong presence overseas, particularly in North America, for over forty years. It has seven factories, a total turnover of $400 million, and its market share in this region is over 20% in its preferred niches of tubes and packaging for the Beauty sector. For the Group, the watchword is more than ever “Made in America for America”! Its main markets are currently personal care, cosmetics in general, and, more specifically, color cosmetics, not to mention oral care and pharmaceuticals.

As for the environmental challenge, the message is clear: “the transition can only be achieved with all the stakeholders in the value chain on board”! Hence the interest in a trade fair such as Luxe Pack New York to exchange ideas with the entire industry.

Explanations by Bruno de Carvalho, Vice President and Managing Director of Tubes, and José Filipe, Vice President and General Manager of the Cosmetics & Fragrance.

Question: In April 2021, i.e. in the midst of the Covid crisis and during an online international press conference, your Group reviewed its presence in the USA and Central America which was pretty significant! What about now?

Bruno de Carvalho: We have three different product lines, Albéa Tubes, Albéa Cosmetics & Fragrance, and IBG (an innovative beauty group, offering turnkey solutions). The first division, which I run, mainly manufactures tubes, the second run, by José Filipe, which has a factory in Mexico, specializes in cosmetics packaging.

Bruno de Carvalho: We have three different product lines, Albéa Tubes, Albéa Cosmetics & Fragrance, and IBG (an innovative beauty group, offering turnkey solutions). The first division, which I run, mainly manufactures tubes, the second run, by José Filipe, which has a factory in Mexico, specializes in cosmetics packaging.

Our Group’s history in America goes back decades. You can’t be more “Made in America” than us. Everything started with the Washington (NJ) factory, which was founded by Bradley Sun Corporation in 1952 to supply extruded plastic tubes. In 1962, Bradley Sun opened its second factory in Shelbyville, Tennessee. Following several changes in control and acquisitions, including American National Can, American Can, Pechiney, Alcan, and Rio Tinto, Albéa Tubes now has five factories in America.

We offer two technologies: laminated tubes and extruded plastic tubes. For the latter category, two factories make them, Washington, NJ, and Reynosa, Mexico. Laminated tubes are manufactured in three factories (two in the USA, the one in Shelbyville, Tennessee, which is one of the largest laminated tube production plants in the world, the other in Washington, NJ, and the third is located in Querétaro, Mexico). Finally, our factory in Canada produces multi-layer films for our laminated tubes, enabling us to offer our customers a complete supply chain made in America. In addition to these production units, we also have several centers of excellence where our global R&D teams collaborate on new package developments. Albea is the unique Tubes supplier producing locally its components, including Aluminum barrier laminate (ABL) and very soon HDPE Greenleaf Recyclable Web, to ensure seamless supply within an environment which is more and more volatile. Our presence in the US is a major asset for our customers in terms of flexibility and security of supply.

And now a few figures…This division employs a thousand people, has a turnover of $200 million, and has a production capacity of 2.5 billion tubes.

José Filipe:The Cosmetic & Fragrance US division is the largest cosmetics packaging manufacturing site in North America, actually located in Matamoros, Mexico, which has a turnover of over $150 million and employs 1,700 people. This single site houses several technologies. It is where lipstick and mascara packs, perfume caps, cases, jars, and bottles are made. We obviously have plating lines as well as decoration equipment (screen printing, pad printing, hot stamping). We also manufacture mascara brushes there.

José Filipe:The Cosmetic & Fragrance US division is the largest cosmetics packaging manufacturing site in North America, actually located in Matamoros, Mexico, which has a turnover of over $150 million and employs 1,700 people. This single site houses several technologies. It is where lipstick and mascara packs, perfume caps, cases, jars, and bottles are made. We obviously have plating lines as well as decoration equipment (screen printing, pad printing, hot stamping). We also manufacture mascara brushes there.

Question: What are the main markets in which you operate?

José Filipe: We are mainly present in the personal care market as well as the color cosmetics market. We have invested some $12 million in our factory in Matamoros over the past two years.

Bruno de Carvalho: Our major customer sectors are cosmetics and personal care (40%), oral care (40%), and pharmaceuticals (20%). There is a clear trend in our customers sourcing in North America instead of Asia. We have invested above $40 in our factories over the past three years, in particular, to adapt them to new constraints related to the placing on the market of innovative, environmentally friendly tubes and to support accelerated growth, particularly with local brands.

Question: What exactly is your Group’s position in the USA regarding the major current issues of the environment and the predominant role of plastic?

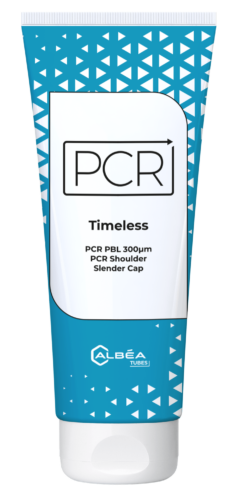

Bruno de Carvalho: In October 2018, our group became the first beauty packaging company to sign the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment. Albéa has undertaken to use 100% reusable and recyclable plastic packaging and 10% post-consumer recycled plastic (PCR) by 2025.

José Felipe: This 2025 commitment is a challenge for our entire industry, and we believe that we can only achieve it in close cooperation with our customers, suppliers, and competitors. The challenge in the hygiene and beauty sector is to make plastic packaging sustainable and integrate it into a circular economy.

To be circular, packaging must be recyclable, but above all it must be recycled, and recycled material must itself be reintegrated into the value chain, i.e. into new packaging. Albéa, as the packaging leader in this industry, has a great responsibility and, today, all our new products are recyclable, incorporate recycled plastic, or have a refill system. However, plastic is and will continue to be a key material in the beauty industry. It remains a material of choice due to its unique properties of lightweightness, strength, versatility, and protection.

Bruno de Carvalho: Albéa has been a proven pioneer in developing and providing its customers with responsible tubes for over a decade with a focus on reducing the use of plastics and improving the circularity of the materials used. Not only does Albéa offer a wide range of recycling-ready, PCR, paper-based, and bio-based tube solutions, it recently introduced the lightest tubes on the market: EcoFusion Top, an innovative packaging solution, with the fusion of the head and the cap, moving from a three-component tube to just two components, with an incomparable design that is responsibly made and recycling-ready.

Our single-material tube solutions aim for a sustainable end-of-life with the possibility of recycling the packaging in existing collection and sorting channels. To advance the circularity of the materials used in Albéa tubes, we cooperate with organizations, such as the Association of Plastic Recyclers (APR) and Stina in the USA and other organizations around the world. In addition, Albea has established exclusive partnerships with major FMCG customers in North America to ensure full recyclable ready packaging.

As a leader in sustainable packaging, Albéa believes that it is its role and responsibility to go beyond inventing and manufacturing responsible packages. The company strives to be an example for its customers, competitors, and other industry participants. With partners across the plastics recycling value chain, Albéa is an active member of the Tube Recycling Project in the US and Europe, a multi-stakeholder initiative addressing barriers and developing solutions that enable market acceptance, sorting, and collection so that consumers can recycle their responsible tubes.

All these actions are recognized and praised by our customers. One recognition that we are particularly proud of is the “Supplier Sustainability Award” that Procter & Gamble awarded us last November. This award recognized six suppliers for their positive impact on P&G’s sustainable development ambitions.

Question: Still a New York Luxe Pack regular?

José Filipe: Of course! We have exhibited at Luxe Pack since the beginning and support this trade fair dedicated to our industry. Personally, I have been going since 2008 and it is always a great event to meet customers and colleagues from the industry.