APTAR BEAUTY: AT THE FOREFRONT NOW MORE THAN EVER!

2023/03/27

LUXE PACK New York 20th Anniversary Pioneers

We are thrilled to be showcasing a very exclusive group of exhibitors who have been part of the 20-year LUXE PACK New York lineage. We are honored to have them continue be part of the invaluable industry legacy that solidifies them as long-running industry packaging players. We would like to introduce them to you individually and therefore welcome you to hone on the special editorial content developed to showcase their own industry legacy and how they plan to continue to contribute to the industry’s next 20.

Articles written by Jean-Yves Bourgeois, Co-founder, LUXE PACK & Founder of Formes de Luxe Magazine

APTAR BEAUTY: AT THE FOREFRONT NOW MORE THAN EVER!

Why was the name ‘Aptar’ chosen? Not many people know the answer to that question. It comes from the Latin ‘Aptare’ which means ‘to adapt’. This was a good choice by the founders of this Group in which was first publicly traded on the New York Stock Exchange in 1993, and grew from founding companies in the US, France and Germany. Today, the Aptar has a turnover of 3.3 billion dollars, with 49 production sites, over 13,500 employees in 20 different countries, has registered more than 1,300 patent families and works with over 5,000 customers around the world. We talked with Laura Estebanez, President, and Amy Hartzell, Vice-President and General Manager, Aptar Beauty North America.

Question: The history of the Aptar Group is incredible, especially the clear vision of its directors as to the direction the products in the beauty industry would evolve!

Laura Estebanez: It is quite fascinating to look back at the history of ‘Aptar’, which began in 1993. In fact, we too are celebrating an anniversary – 30 years on the New York Stock Exchange. Adaptability & flexibility have always been the key to Aptar’s success. Our motto: “Transforming ideas into solutions that improve everyday life”. We are committed to providing innovative dispensing solutions for beauty brands around the world. We focus on manufacturing high value-added dispensing systems for fragrance, make-up, skin care and personal care products. Personal care accounts for 42% of our business and Beauty in general for 51%. Our strongest region for sales remains Europe (55%), followed by North America (26%), South America (12%) and Asia (7%). We have a strong “think local, leverage global” industrial strategy with several sites in Latin America, France, Germany, Italy, the United States and China. This has led to major investments in terms of industrial capability in the United States, particularly in the airless sector (+30%). In North America Beauty, we have roughly 850 employees and four manufacturing sites.

Laura Estebanez: It is quite fascinating to look back at the history of ‘Aptar’, which began in 1993. In fact, we too are celebrating an anniversary – 30 years on the New York Stock Exchange. Adaptability & flexibility have always been the key to Aptar’s success. Our motto: “Transforming ideas into solutions that improve everyday life”. We are committed to providing innovative dispensing solutions for beauty brands around the world. We focus on manufacturing high value-added dispensing systems for fragrance, make-up, skin care and personal care products. Personal care accounts for 42% of our business and Beauty in general for 51%. Our strongest region for sales remains Europe (55%), followed by North America (26%), South America (12%) and Asia (7%). We have a strong “think local, leverage global” industrial strategy with several sites in Latin America, France, Germany, Italy, the United States and China. This has led to major investments in terms of industrial capability in the United States, particularly in the airless sector (+30%). In North America Beauty, we have roughly 850 employees and four manufacturing sites.

Question: A journey most often marked by successive acquisitions.

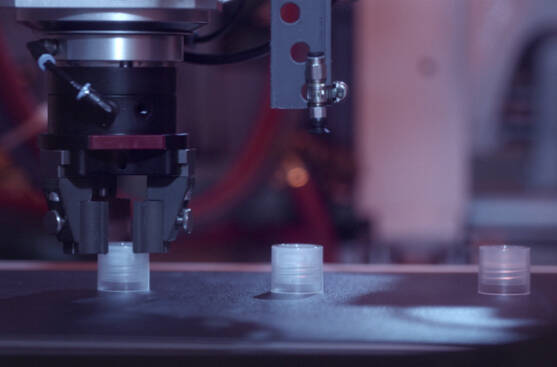

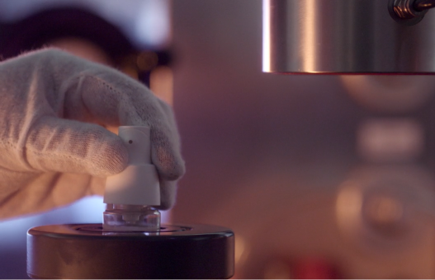

Laura Estebanez: That is true and a little bit more complex than that. Our most recent acquisition is of iD SCENT, a leading manufacturer in sustainable paper fragrance sampling products. We also acquired FusionPKG in 2020, one of the leaders in high-end cosmetic packaging (airless and make-up packaging, turnkey solutions) for the North American market. A major acquisition since it thrusted us into the world of full service and gave us access to markets such as the Indie brands. Prior to this acquisition was that of Reboul in 2018, the French leader of high-quality metal components, metal-plastic sub-assemblies, new generation lipstick mechanisms and complete make-up packaging solutions. In 2019, Aptar invested in the TerraCycle LOOP Global circular purchasing platform, which delivers consumer products in re-useable containers and also invested in PureCycle, with rigorous prototype testing of its ultra-pure recycled (UPR) plastic to integrate more recycled content into packaging for the food, beverage and cosmetics industries. In 2021 we opened our InVision Innovation Lab near to Paris to create innovative solutions together with our customers, while showcasing our technological innovations and creative capabilities. In 2022, we opened the Go2Lab innovation center in North America, offering on-site services to speed up product development and innovation (sampling, lab testing, custom design and development, functional prototypes, as well as tooling and molding). Brands can partner with Aptar to conceptualize through workshops and ideation sessions with our seasoned industry experts ready to guide them in the process. The launch of this facility is pioneering the way in finding faster packaging solutions to address innovation needs driven by consumer trends. Traditionally, launching products to market has lead times that can be as far out as six months. Our services help brand partners reduce those lead times to weeks with the accessibility of our 3D printing and prototyping capabilities, lab services, and fast tooling. This will allow brands to launch their beauty products to market faster. We are also opening a new 25,000 m² state-of-the-art facility in France (Oyonnax) in 2023, with extensive expertise on exemplary environmental standards and strong innovation capabilities to position us as a leading provider of sustainable and fully customizable luxury solutions. Our strategy has always been to produce locally to serve locally but we will continue to leverage our global capabilities to serve the needs of our clients in NA.

Question: And obviously the environment is a major consideration!

Amy Hartzell: We have a clear objective. We want to transform ideas into solutions to improve daily life, taking into account all aspects of our work, including our approach to sustainability of course. And in the same way that we take care of each other and the planet, we work with brands and push the circular economy forward.We have and will continue to meet all the associated technical and regulatory steps. We have received the highest award from EcoVadis. The Platinum level rating places Aptar among the top 1% of nearly 90,000 companies that have been rated by EcoVadis in all business sectors. We received an award from the Plastic Recyclers Association for our SimpliCycle™ recyclable valve.We are recognized as a preferred testing partner for PureCycle Technologies’ ultra-pure recycled plastic. We launched an internal circular economy awareness training course, developed in partnership with the Ellen MacArthur Foundation. Newsweek named us as one of the most responsible American companies in 2023, placing us in 15th position out of 500 American companies and in first place in the industrial company category. We were also named one of Barron’s 100 Most Sustainable Companies for the fifth year in a row and are ranked #55 out of 100 companies for 2023.

Amy Hartzell: We have a clear objective. We want to transform ideas into solutions to improve daily life, taking into account all aspects of our work, including our approach to sustainability of course. And in the same way that we take care of each other and the planet, we work with brands and push the circular economy forward.We have and will continue to meet all the associated technical and regulatory steps. We have received the highest award from EcoVadis. The Platinum level rating places Aptar among the top 1% of nearly 90,000 companies that have been rated by EcoVadis in all business sectors. We received an award from the Plastic Recyclers Association for our SimpliCycle™ recyclable valve.We are recognized as a preferred testing partner for PureCycle Technologies’ ultra-pure recycled plastic. We launched an internal circular economy awareness training course, developed in partnership with the Ellen MacArthur Foundation. Newsweek named us as one of the most responsible American companies in 2023, placing us in 15th position out of 500 American companies and in first place in the industrial company category. We were also named one of Barron’s 100 Most Sustainable Companies for the fifth year in a row and are ranked #55 out of 100 companies for 2023.

Question: Your Group has always been committed to innovation!

Amy Hartzell: Absolutely! A perfect example is “Amplitude” which is a higher-dosage treatment dispensing pump that offers aesthetic form with quality and performance and a twist-to-lock feature that eliminates the need for an over cap. It features a smooth, soft actuation and excellent priming for a premium product experience. “Amplitude” is compatible with a wide range of formulas and is available in two dosage options. Future, our award-winning, innovative dispensing pump is another great example. Future is mono-material and fully-recyclable when paired with a PE or PET bottle. It is also ISTA 6-Amazon Certified which renders it e-commerce capable. Thanks to its incorporated locking/unlocking ring, and features a 360° degree, free spinning actuator which helps minimize potential breakage in transit. Future is suitable for a range of viscosities, customizable with two dosage options and three neck size options, and is available in a variety of colors thanks to its unique, three-part design. The brand Dermalogica® has chosen ‘Future’, our fully recyclable single-material pump for the launch of its latest product line, collectively winning four awards.

Question: That really is impressive! Do you have any other recent news other than just pumps?

Amy Hartzell: Yes of course! In North America we continue to expand the portfolio of sustainable dispensing solutions with the addition of two aerosol actuators (Moritz and Markus) and fine mist spray (EuroMist), now qualified in up to 46% Post-Consumer Recycled Resin (PCR). In lipsticks, we developed a mechanism for smart and attractive refills, called Private Refill. It connects with a single click to a specific lipstick base and features a patented security key unique to each client and project. Brands can be confident that their refill cannot be used alone or with another lipstick mechanism. We recently launched this solution with Clarins Joli Rouge in EMEA. And to round off, over the last two years, we have redesigned a large part of our range of pumps, caps, closures, airless and aerosols to make them e-commerce compatible. Today, about sixty omnichannel packaging options from our Beauty catalog are certified ISTA 6-Amazon.