BORMIOLI LUIGI: Constantly Adapting!

2023/02/27

LUXE PACK New York 20th Anniversary Pioneers

We are thrilled to be showcasing a very exclusive group of exhibitors who have been part of the 20 year LUXE PACK New York lineage. We are honored to have them continue be part of the invaluable industry legacy that solidifies them as long running industry packaging players. We would like to introduce them to you individually and therefore welcome you to hone on the special editorial content developed to showcase their own industry legacy and how they plan to continue to contribute to the industry’s next 20.

Articles written by Jean-Yves Bourgeois, co-founder, LUXE PACK & Founder of Formes de Luxe Magazine.

1946, 2023…, 77 years ago, Luigi Bormioli officially incorporated the Bormioli Luigi glassworks, which is currently a world leader in the manufacture of bottles and jars for fragrances and cosmetics as well as tableware. The balance sheet is impressive with 600 million euros in sales for a workforce of over 2,300 people working in five glassworks and three decoration plants. It is even more impressive given that the company is still 100% family-owned. As for the Group’s presence in the U.S.A., where the subsidiary employs eighteen people, it has continued to strengthen in the cosmetics and fragrances niche. Interview with Simone Baratta, Head of the Beauty Business Unit.

Question: Bormioli Luigi’s story goes back much further, and, surprisingly, the family was originally French!

Simone Baratta: That’s right! Our company’s origins date back to the Middle Ages. In the nineteenth century, the Borniolle family, which specialized in glassmaking, moved from France to Altare, in the province of Savone, Italy, where it changed its name to Bormioli. In 1825, the family moved from Liguria to Fidenza in the province of Parma and expanded its business in the Emilia-Romagna region. In 1946, Luigi Bormioli officially founded the Bormioli Luigi glassworks. It was only in the 1980s-2000s that the Group expanded its business to the luxury fragrances sector. In 2007, a new plant was acquired in Abbiategrasso, near Milan, which allowed the company to increase its production by 30%. In 2013, a new division called the Afterglass Factory, specializing in glass decorations, opened at the Parma factory.

Simone Baratta: That’s right! Our company’s origins date back to the Middle Ages. In the nineteenth century, the Borniolle family, which specialized in glassmaking, moved from France to Altare, in the province of Savone, Italy, where it changed its name to Bormioli. In 1825, the family moved from Liguria to Fidenza in the province of Parma and expanded its business in the Emilia-Romagna region. In 1946, Luigi Bormioli officially founded the Bormioli Luigi glassworks. It was only in the 1980s-2000s that the Group expanded its business to the luxury fragrances sector. In 2007, a new plant was acquired in Abbiategrasso, near Milan, which allowed the company to increase its production by 30%. In 2013, a new division called the Afterglass Factory, specializing in glass decorations, opened at the Parma factory.

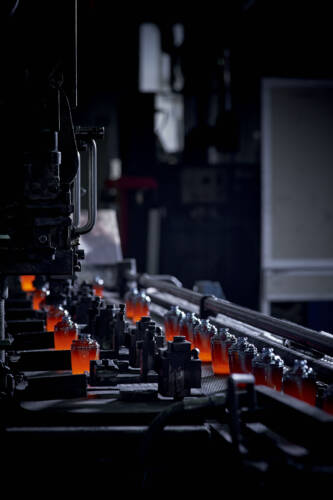

In 2017, Bormioli Luigi Group acquired Bormioli Rocco’s Tableware division. This allowed us to expand our sphere of influence and increase our production capacity. In 2020, a sales office opened in Sao Paulo, Brazil. Finally, in 2022, a new production line was inaugurated at the existing plant in Azuqueca, Spain. This plant, located 40 km from Madrid and owned by Bormioli Rocco, was acquired by our Group in 2017. It only produced tableware items. At the time, it was decided to gradually convert it into a plant dedicated to the fragrances and cosmetics sector. To do this, we decided to gradually install four new IS machines to manufacture vials, jars, and home fragrance containers: one, in 2022, then a second and third in 2023, and a fourth next year. In general, we use our expertise in the various glass technologies to increase our scope in the beauty sector.

Question: In an interview in 2008, Alberto Bormioli stated: “I prefer to put money in machines rather than in the bank”. He wanted to demonstrate his desire to invest in the right “production tool” for the right market! This is all the more relevant now.

Simone Baratta: All the more relevant, that’s true! Because, despite the high pressure from rising production costs, we continue to invest in our different units to meet increasing demand. A glassworks that does not innovate and does not invest will gradually lose out! In total, 200 million euros have been invested in innovation, sustainable development, and production capacity, taking us up to 2024. This includes investments in Spain to meet the growing needs of the beauty sector through product innovations to provide eco-responsible solutions with a 50% carbon intensity reduction target for 2030. It also includes investments to complete our Afterglass Factory (between eight and ten million euros between 2019 and 2024).

Question: The environment is a huge challenge for you, of course.

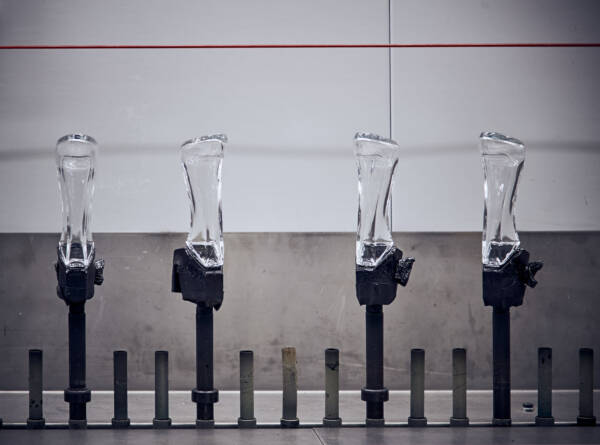

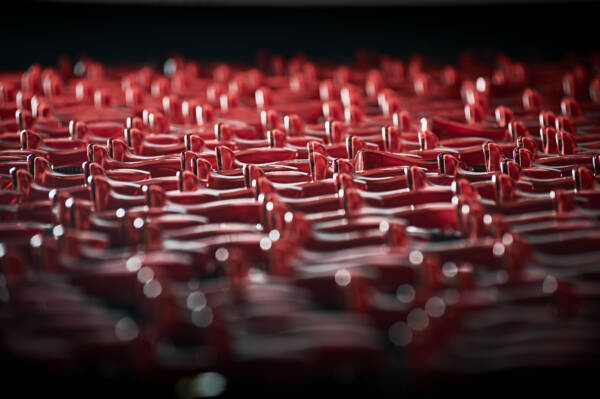

Simone Baratta: Yes, of course, but glass, a material that is 100% recyclable and which can be recycled endlessly, has undeniable advantages as brands and consumers seek solutions that are both more premium and more sustainable. To meet these expectations, we are developing numerous innovations (lightweight solutions, recycled glass, interchangeable rings, etc.). Our Ecoline range allows us to offer a series of vials and jars with ultra-lightweight glass screw caps (58% lower weight compared to a conventional container). In terms of new products, we have developed a line of glass packaging for make-up (refillable lipstick, lip gloss, and mascara). Interchangeable rings are intended for the perfume and skincare markets and the development of refillable systems. This results in a significant reduction in the number of tooling components and costs.

As for the use of PCR (Post-Consumer Recycled) glass, the demand for which is constantly increasing, most Premium brands demand it. The aim is to ensure that the percentage of PCR used is as high as possible without losing the quality of the vial or jar. This is not easy because resources in this field are limited and the quality is extremely variable. This requires us to be under contract with well-targeted service providers in order to sustain our supplies and our offering.

Question: Which “flagship” products have been developed and marketed in recent months?

Simone Baratta: We have developed a lot of things recently. The market has been particularly buoyant and dynamic, especially in fragrances, both in Europe and the U.S.A. This includes a whole new collection of ultra-lightweight glass products, the development of a “refillable” jar (this model contains a removable glass cup that the consumer can buy in-store and easily replace. Its patented design is based on a special design with a plastic ring that provides security, sealing, and support. This sustainable packaging solution promotes a design that is all the more premium as its service life is ensured), and our Skin Lock system, which minimizes the amount of plastic used in packaging, that combines a glass cap and jar. The closure system is comprises a plastic ring that seals the pack and keeps the parts in place through compression. This secures the product, keeps the pack airtight, and preserves the formula.

Regarding our developments for the mascara and lipgloss/lipstick markets, turnkey solutions include the vial and a ready-to-use application system. The decoration and shape (square section, oval, etc.) of the products can be customized.

For lipstick, the case comprises a glass base and a glass cap connected to an insert containing the lipstick tube. It is refillable, and the consumer can change the lipstick tube at the end of its life or alternate shades as desired while keeping the case.

The latest launch in this area is the refillable “Tango” lipstick made of glass and wood, created in cooperation with the Italian company mPackting, which belongs to the Minelli Group. The grained wood gives it a special look and feel. The glass adds to this “Premium” spirit, and its transparency gives an impression of lightness.

Question: Energy must be a particularly sensitive topic for a glassworks.

Simone Baratta: You can say that again! I would say it is essential. Regarding the Beauty sector, our production tool is clearly evolving towards electric or hybrid furnaces. I would like to remind you that our goal is to halve our CO2 emissions by 2030.

Question: You’ve been loyal to Luxe Pack!

Simone Baratta: Of course! Without a doubt, these trade fairs are relevant to us, with the right positioning.